cnc machine g code meaning G code, sometimes called g-code, is a simple programming language for CNC machines. Listed below are the codes that use the G word. These codes are preparatory commands. This means that they set modes or . Receive precisely crafted CNC machined aluminum parts from an industry leader since 1975. Why choose Moseys for your CNC aluminum parts needs? High-precision machining capabilities –producing custom aluminum parts from .050” diameter to a 24” cube. Receive custom aluminum parts on time –with 99.1% On-Time Delivery (OTD).

0 · how to understand g code

1 · g code explained with examples

2 · g code commands cheat sheet

3 · free downloadable g code files

4 · complete g code list

5 · cnc mill g code list

6 · cnc machine g code list

7 · cnc g code cheat sheet

Our state-of-the-art facility offers custom metal stamping parts with advantages over our competitors. Learn how Winco can help you today!

G code, sometimes called g-code, is a simple programming language for CNC machines. Listed below are the codes that use the G word. These codes are preparatory commands. This means that they set modes or . What is a G code? G-code is the common name for the most widely .

G-code is the primary programming language of CNC machines. It relates to the geographical coordinates of the machine arm so that it knows how and where to move. Without this code, your CNC machine would be a . G-codes and M-codes serve distinct yet complementary roles in CNC programming. G-codes focus on controlling the geometry and movement of the CNC machine, . G-code is a CNC programming language that directs a CNC machine’s functions related to the cutting tool’s movement. It stands for ‘Geometric code.’ G-code guides the CNC machine’s actions by combining .Simply put, G-code is a software programming language used to control a CNC machine. And, even with complex CNC machining, G-code is written in a straightforward, logical way. A “ G ” is followed by a number, which is a .

G-code is the name of a plain text language that is used to guide and direct CNC machines. For most modern CNC machines, it isn‘t necessary to know the meaning of G-codes since CAD and CAM software is translated into G or M .

G-Code is the most common programming language. A G-Code in CNC Programming works like a controller and dictator. It controls the machine’s movement and dictates how and where it should move to formulate the end .

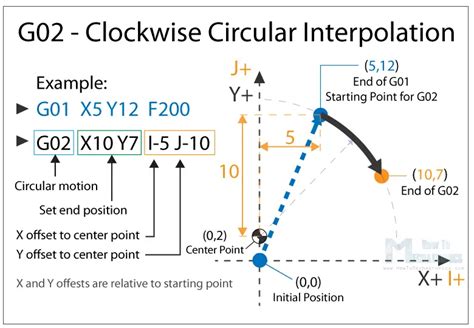

G-code is the language used to control CNC machines. It stands for 'Geometric Code' and consists of a series of commands that tell the machine what actions to perform, such as moving to a specific point, cutting at a particular speed, or . G code, sometimes called g-code, is a simple programming language for CNC machines. Listed below are the codes that use the G word. These codes are preparatory commands. This means that they set modes or prepare the machine for various actions. We have put together a complete list of G codes for your reference. Not all codes are used often.What is a G code? G-code is the common name for the most widely used CNC programming language. It was developed in the 1950s at MIT. The language is very “primitive” by today’s standards. All the commands are represented by codes (G01, G02, .

Manufacturers all around the world use CNC programming to control a machine’s tools to produce parts. At the heart of this automated manufacturing process is a set of instructions that tells a CNC machine where – and how – . G-code is the primary programming language of CNC machines. It relates to the geographical coordinates of the machine arm so that it knows how and where to move. Without this code, your CNC machine would be a stationary device, such as a router or lathe.

G-codes and M-codes serve distinct yet complementary roles in CNC programming. G-codes focus on controlling the geometry and movement of the CNC machine, dictating how the tool should move along different axes and the paths it should follow to create specific shapes.

G-code is a CNC programming language that directs a CNC machine’s functions related to the cutting tool’s movement. It stands for ‘Geometric code.’ G-code guides the CNC machine’s actions by combining instructions readable by the microcontroller.Simply put, G-code is a software programming language used to control a CNC machine. And, even with complex CNC machining, G-code is written in a straightforward, logical way. A “ G ” is followed by a number, which is a command to change geometry.

G-code is the name of a plain text language that is used to guide and direct CNC machines. For most modern CNC machines, it isn‘t necessary to know the meaning of G-codes since CAD and CAM software is translated into G or M codes to instruct a . G-Code is the most common programming language. A G-Code in CNC Programming works like a controller and dictator. It controls the machine’s movement and dictates how and where it should move to formulate the end CNC machined product. M-Code is used for specific applications.

G-code is the language used to control CNC machines. It stands for 'Geometric Code' and consists of a series of commands that tell the machine what actions to perform, such as moving to a specific point, cutting at a particular speed, or performing a specific operation. G code, sometimes called g-code, is a simple programming language for CNC machines. Listed below are the codes that use the G word. These codes are preparatory commands. This means that they set modes or prepare the machine for various actions. We have put together a complete list of G codes for your reference. Not all codes are used often.

how to understand g code

What is a G code? G-code is the common name for the most widely used CNC programming language. It was developed in the 1950s at MIT. The language is very “primitive” by today’s standards. All the commands are represented by codes (G01, G02, . Manufacturers all around the world use CNC programming to control a machine’s tools to produce parts. At the heart of this automated manufacturing process is a set of instructions that tells a CNC machine where – and how – . G-code is the primary programming language of CNC machines. It relates to the geographical coordinates of the machine arm so that it knows how and where to move. Without this code, your CNC machine would be a stationary device, such as a router or lathe. G-codes and M-codes serve distinct yet complementary roles in CNC programming. G-codes focus on controlling the geometry and movement of the CNC machine, dictating how the tool should move along different axes and the paths it should follow to create specific shapes.

G-code is a CNC programming language that directs a CNC machine’s functions related to the cutting tool’s movement. It stands for ‘Geometric code.’ G-code guides the CNC machine’s actions by combining instructions readable by the microcontroller.Simply put, G-code is a software programming language used to control a CNC machine. And, even with complex CNC machining, G-code is written in a straightforward, logical way. A “ G ” is followed by a number, which is a command to change geometry.G-code is the name of a plain text language that is used to guide and direct CNC machines. For most modern CNC machines, it isn‘t necessary to know the meaning of G-codes since CAD and CAM software is translated into G or M codes to instruct a . G-Code is the most common programming language. A G-Code in CNC Programming works like a controller and dictator. It controls the machine’s movement and dictates how and where it should move to formulate the end CNC machined product. M-Code is used for specific applications.

indian tiffin box stainless steel

industrial electrical enclosure

Meichuang provides high-quality sheet metal parts for a wide range of industries and applications. Our expert team ensures precision and accuracy in the production of custom sheet metal parts, including laser cutting, bending, welding, and finishing.

cnc machine g code meaning|cnc g code cheat sheet